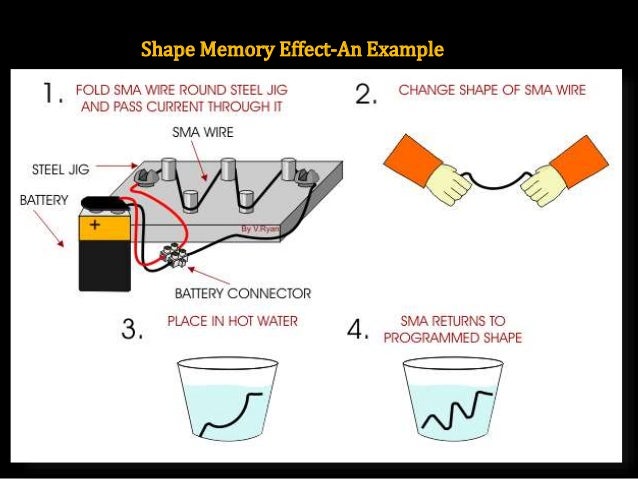

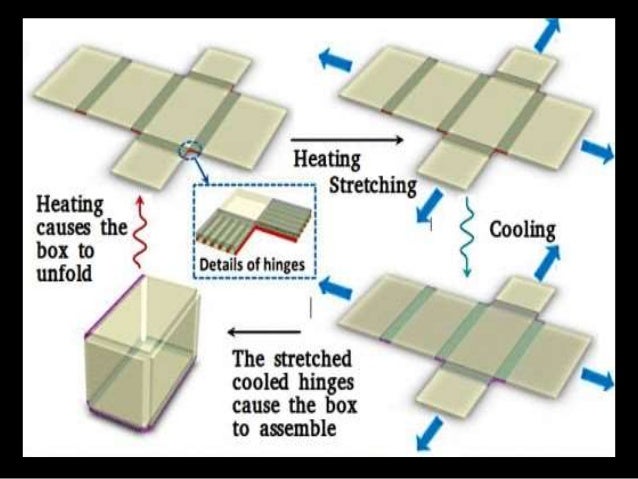

They form and deform when heat or thermal energy is applied as a stimulus. Most of the researchers prefer SMPs as it becomes easy to print on these materials. They are classified into Shape Memory Alloys (SMA), Shape Memory Polymers (SMP), Shape Memory Hybrids (SMH), Shape Memory Ceramics (SMC), and Shape Memory Gels (SMG). These materials work on the mechanism of the Shape Memory Effect (SME). Current classes of smart materials are currently classified into the below categories: Materials for 4D printing are classified based on their environment or the external stimuli they react with. It predicts the deformation (forward) and formation (backward) process of an object triggered by stimuli. Research on Mathematical Modeling is essential in understanding the functional structures of 4D printed objects. Currently, researchers use direct inkjet cure, fused deposition modeling, stereolithography, laser-assisted bioprinting, and selective laser melting methods for 4D printing. Equipment Design deals with developing advanced printer technology, which can print multiple materials congruently. Smart Material is one of the highly focused research areas in 4D printing, wherein the deformation mechanism of various materials is synthesized as per their responses to various external stimuli. The primary research areas currently in focus with respect to 4D printing are depicted in the Exhibit 3 below. However, research and advancement in 3D printing are expected to provide new opportunities for 4D printing. 4D Printing Materials and Technologies Major Research AreasĪs the 4D printing technology is still in its nascent stage, materials used for it are minimal. Exhibits 1 and 2 depicted below explain the major differences between 3D and 4D printing. The major differences between 3D printing and 4D printing are the use of materials to be printed and the printing facility. This capability of objects to transform their structure over time by using the behavior of different materials is termed as 4D printing. Researchers are further working on expanding these structural changes to create lockers, lifters, microtubes, soft robots, toys, etc. The congruent printing of different materials will form material anisotropy, which enables the object to change the structure by bending, elongating, twisting, and corrugating along its axes. The meta-material structure is generated by combining different materials that provide superimposed structural responses when activated by external stimuli. Researchers are currently looking ahead of conventional 3D printing, which fabricates structures from a single material, to develop a meta-material structure. The increasing need for flexible objects in various applications, such as self-folding packaging, adaptive wind turbines, etc., has fueled the emergence of 4D printing.

Despite its ability to create complex, bio-inspired, multi-material designs, 3D printing is not yet ready to be adopted in large-scale manufacturing. 3D printing technology has witnessed continuous advancements over the last 3 decades and has evolved drastically. 3D printing enables manufacturers and researchers to develop complex shapes and structures, which were earlier considered impossible with traditional fabrication methods.

It has completely transformed the way parts/components and equipment are manufactured in the industry, along with their design and development. Emergence of 4D Printing from 3D PrintingģD printing, an additive manufacturing technique, is considered as one of the most disruptive innovations in the field of modern manufacturing. This shape-changing phenomenon of 3D printed objects is based on the material’s ability to transform over time in response to specific stimuli, and it does not require human intervention to aid the process. By integrating the dimension of time, printed objects change their shape dynamically based on the needs and demands of the situation, without any electromechanical parts or moving parts. With this new dimension, 3D printed objects possess the capability to change its shape by itself over the influence of external stimuli, such as light, heat, electricity, magnetic field, etc. The introduction of the fourth dimension to the 3D printing technology is termed as “4D Printing”.

0 kommentar(er)

0 kommentar(er)